Subsystem Verification (SSV)

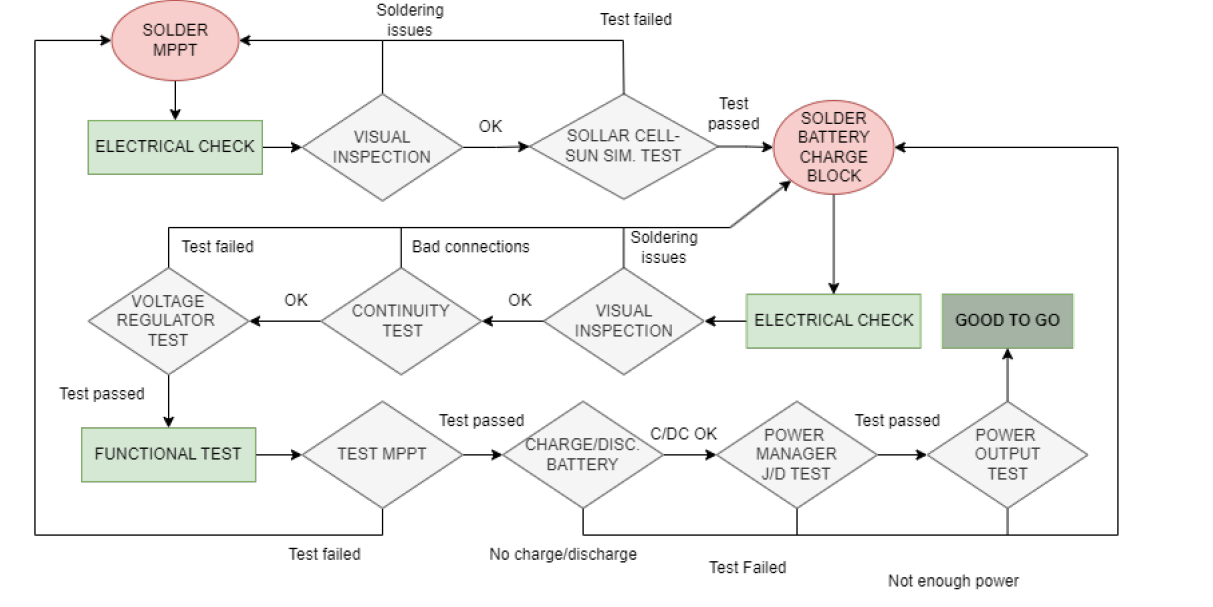

The EPS consists of two main blocks. The process begins by soldering the MPPTs, and with the help of a solar simulator, they are tested using a solar cell to ensure proper functionality and that the output is as expected.

Next, the Battery Charge Block is soldered, followed by a visual inspection and continuity test to ensure there are no short circuits. Using a power supply, it is verified that the battery can provide a steady 3.3V output at the EPS output. The same test is conducted with the solar cells.

A battery charging test is performed using the solar cells to confirm that the battery charges correctly. The battery sensor is checked to ensure it reads accurate values, and the I/O pins of the Power Management IC are tested for proper operation. Finally, it is verified that the output can supply power to a load through the EPS output.

Figure 1: EPS SSV Block Diagram

No Comments